3D Printing: Basics you wanted to know

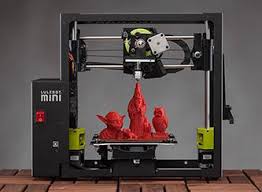

3D printing has become a magical reality across the world in a short span of time. The acceptance of 3D printing has prompted many observers to describe it the next Industrial revolution. The technology was invented in the 1980s. But the exorbitant costs prevented its popularity. After the expiry of patent, many companies ventured into the field making the technology more popular and affordable. The initial usage was around prototype manufacturing. As of now, 3D technology is being used even in mass manufacturing of various products of different shapes and designs. Imagination has become the limit for 3D printing technology.

What is 3 D printing?

In simple terms, 3D printing is a technology of creating three dimensional solid objects from a digital image or file. The process is also called additive manufacturing. The three dimensional model is created by laying down thin layers of material continuously which is controlled by a computer programme. Thus, a Computer Aided Design (CAD) becomes a physical model.

What is additive manufacturing or printing?

During the construction of a wall, we keep brick over brick by keeping a layer of binding material in between. The process involved in additive manufacturing or printing is almost same. In this process, a three dimensional object or model is created by arranging continuous layers of material till the model is manufactured. Each layer represents a thin, horizontal cross section of the final model. The entire process is controlled by computer. As of now, there are seven different types of additive manufacturing processes namely, binder jetting, directed energy deposition, material jetting, powder bed fusion, material extrusion, sheet lamination and vat photopolymerization.

What are the processes involved?

3 D Model preparation

The first step involved is creation of virtual design of the object, which is normally a CAD file. This model can be created using a 3D modeling application or with a 3D scanner. 3D scanner can be used when a 3D digital copy of an object is to be created.

Companies like Google and Microsoft have introduced 3D scanners. Microsoft’s Kinect is such a hardware. It is expected that in future, smartphones will have 3D scanners and scanning will become a simple feature like photography.

Slicing:

Slicing is the process of conversion of 3D design to printable format. In this technique, the 3D model is divided into large number of horizontal layers. This process can be carried out by using software applications. Software like Tinkercard supports the scanning and slicing processes.

Printing process:

On completion slicing, the model is ready to print. It can be fed into a 3D printer using USB, SD or Wi-Fi, depending on the type of printer used. Each slice is read by the printer and the 3 dimensional object is created by laying one layer over the other layers. In certain cases, the printed object is smoothed using chemical solvents as part of finishing

What are the applications of 3D printing?

3D printing finds applications in areas like prototype manufacturing, jewellery design, automobile components manufacturing, furniture components, bridge, building and vehicle designs and even in human body part manufacturing. The technology presently finds application in prototyping, custom –building and create limited edition products to test the market. With the technology becoming cheaper, it will find varying applications.